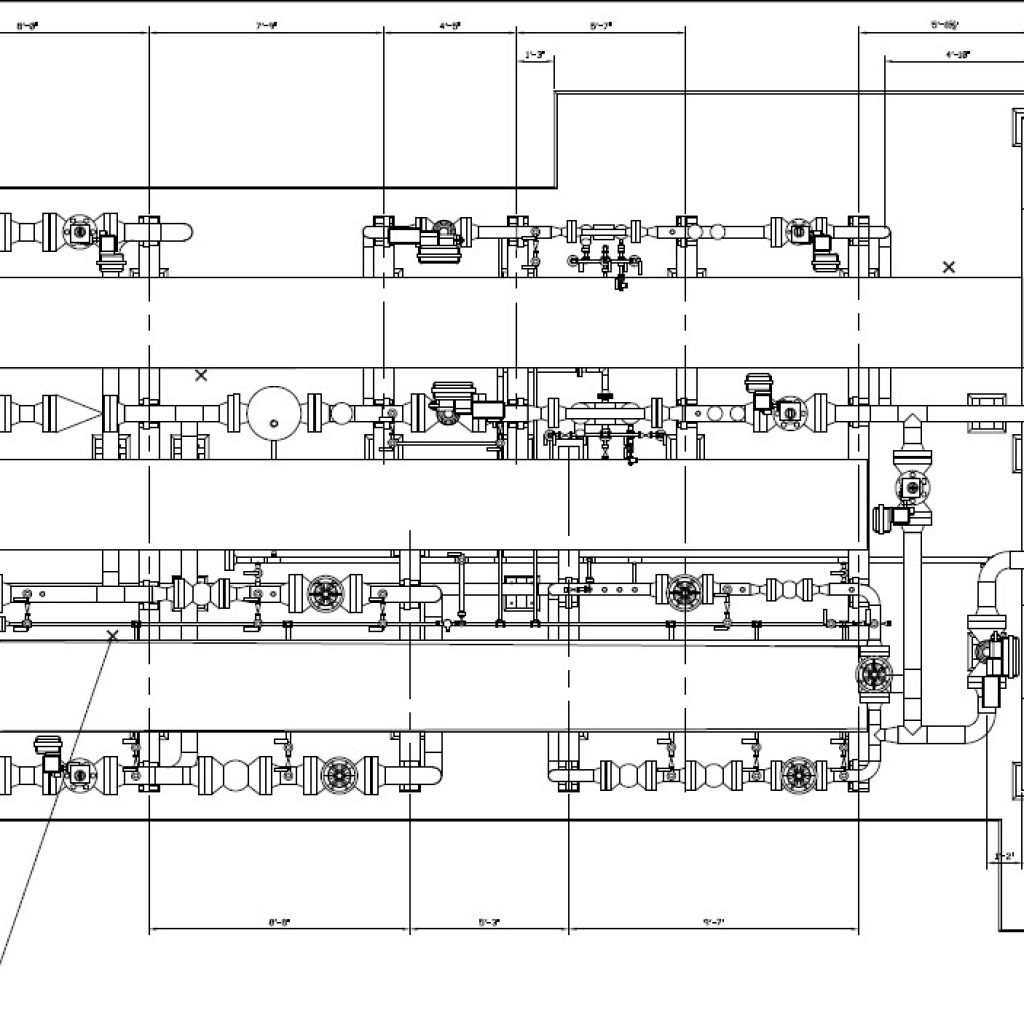

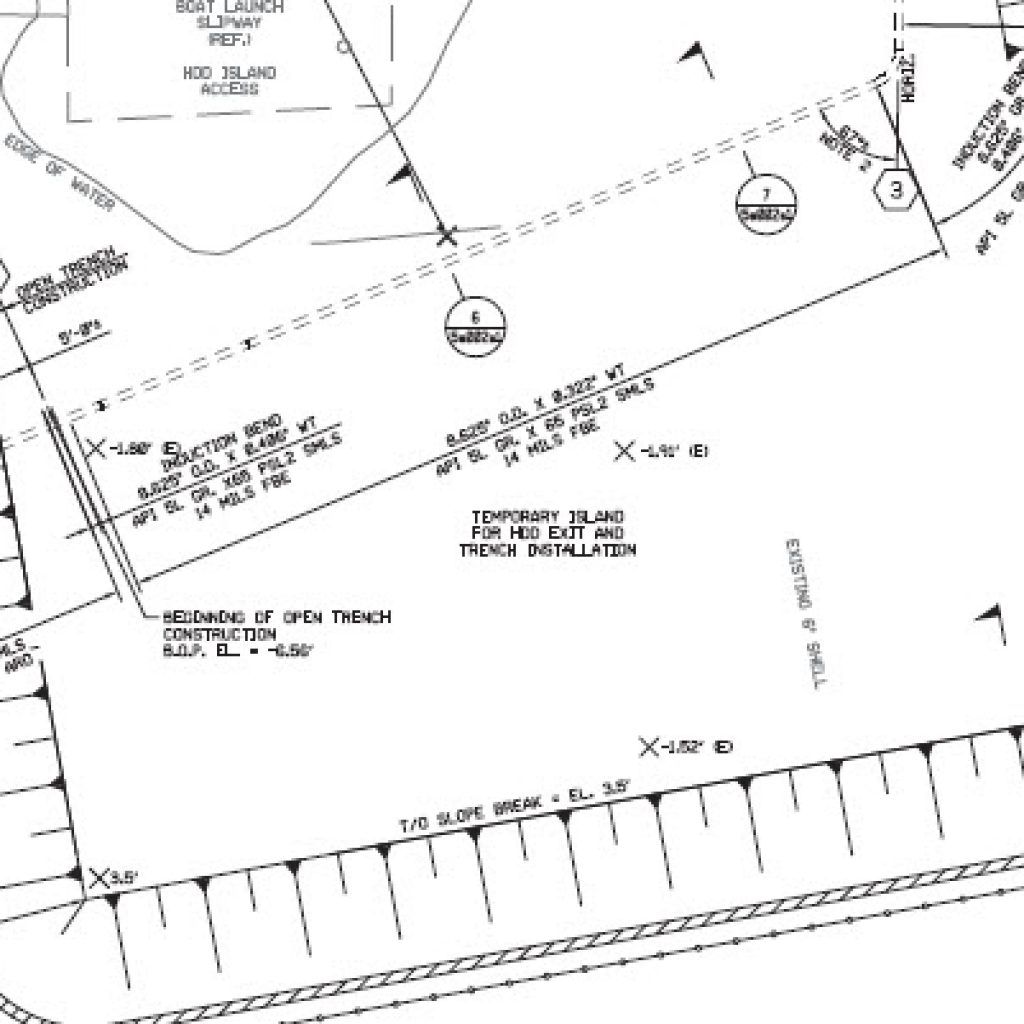

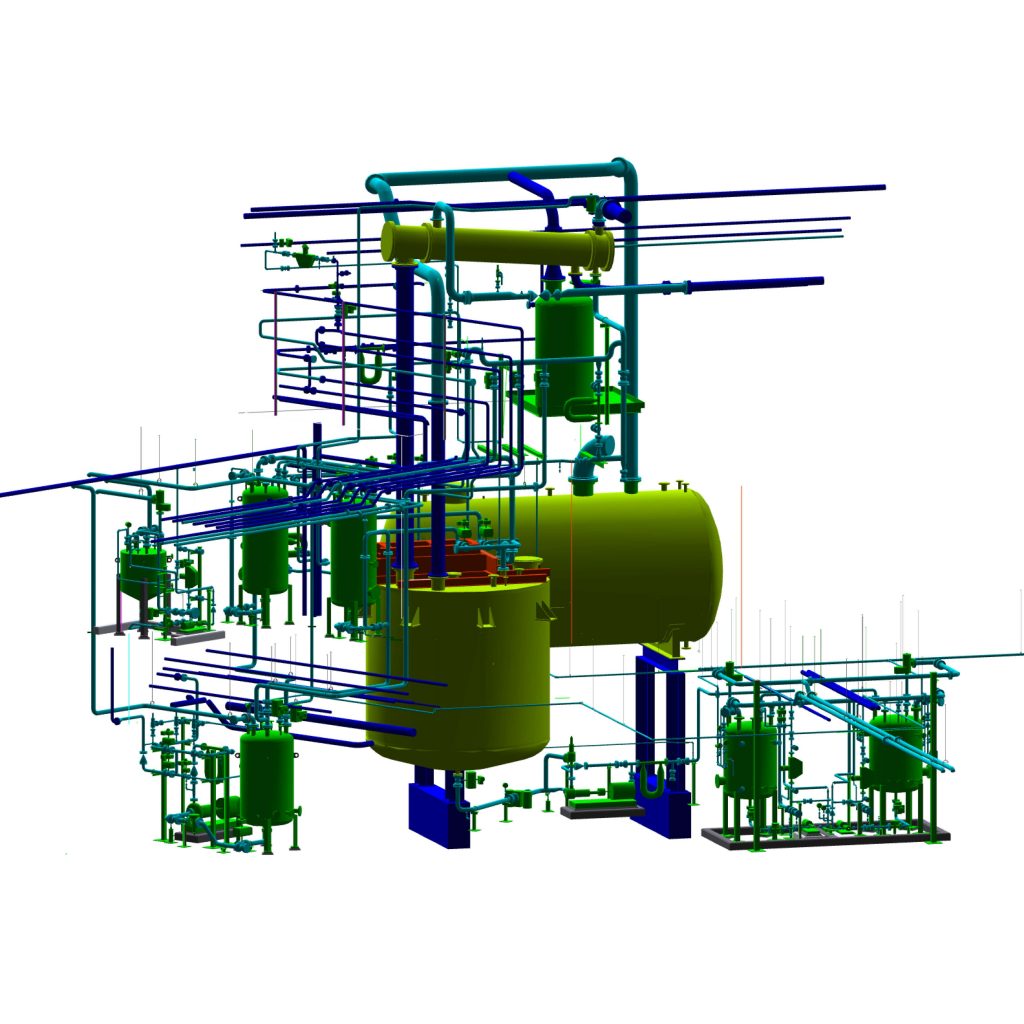

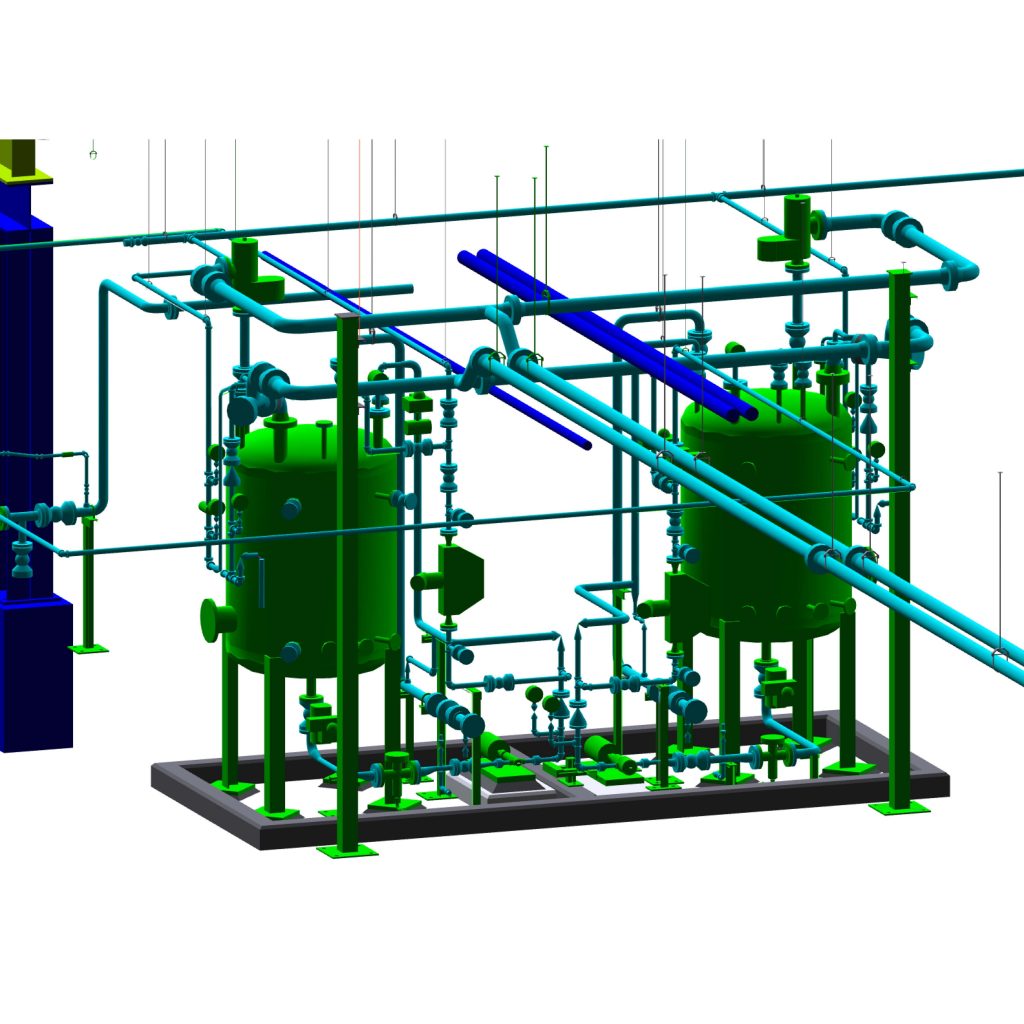

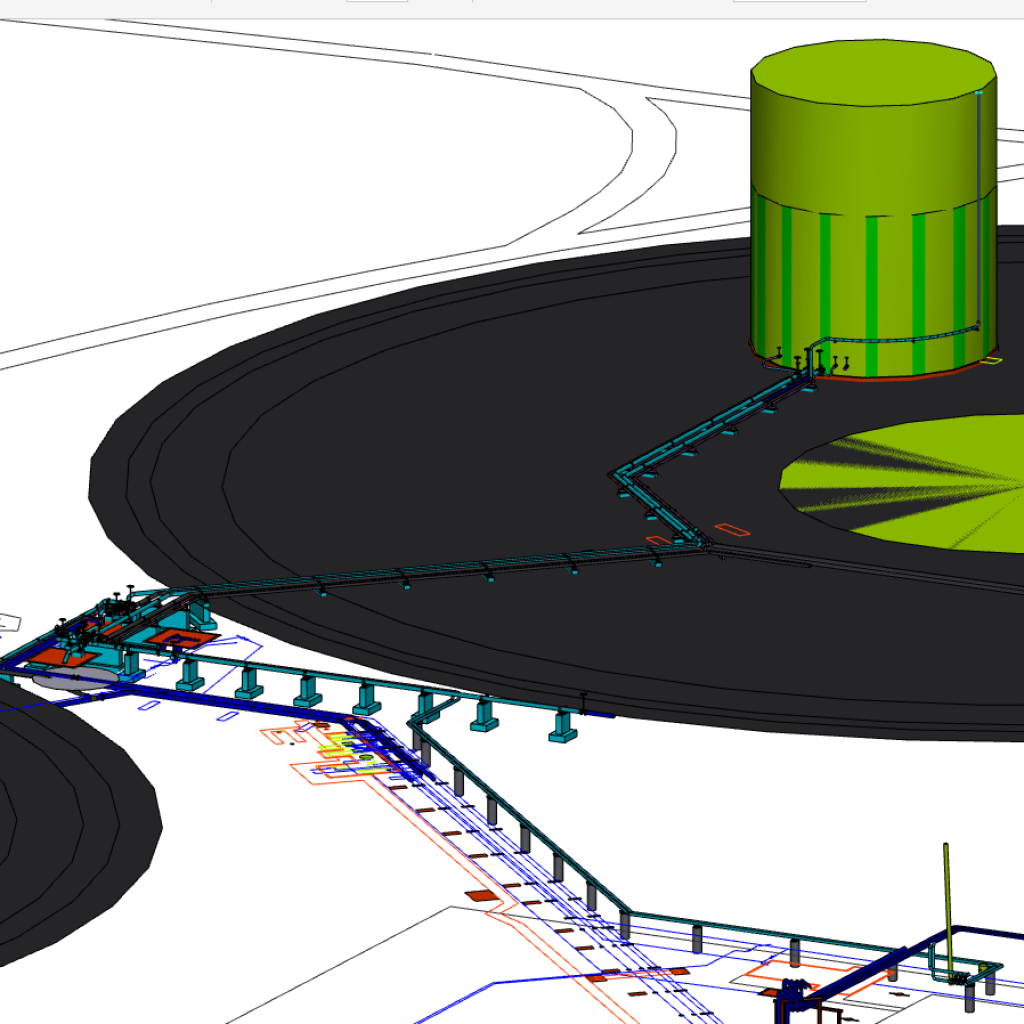

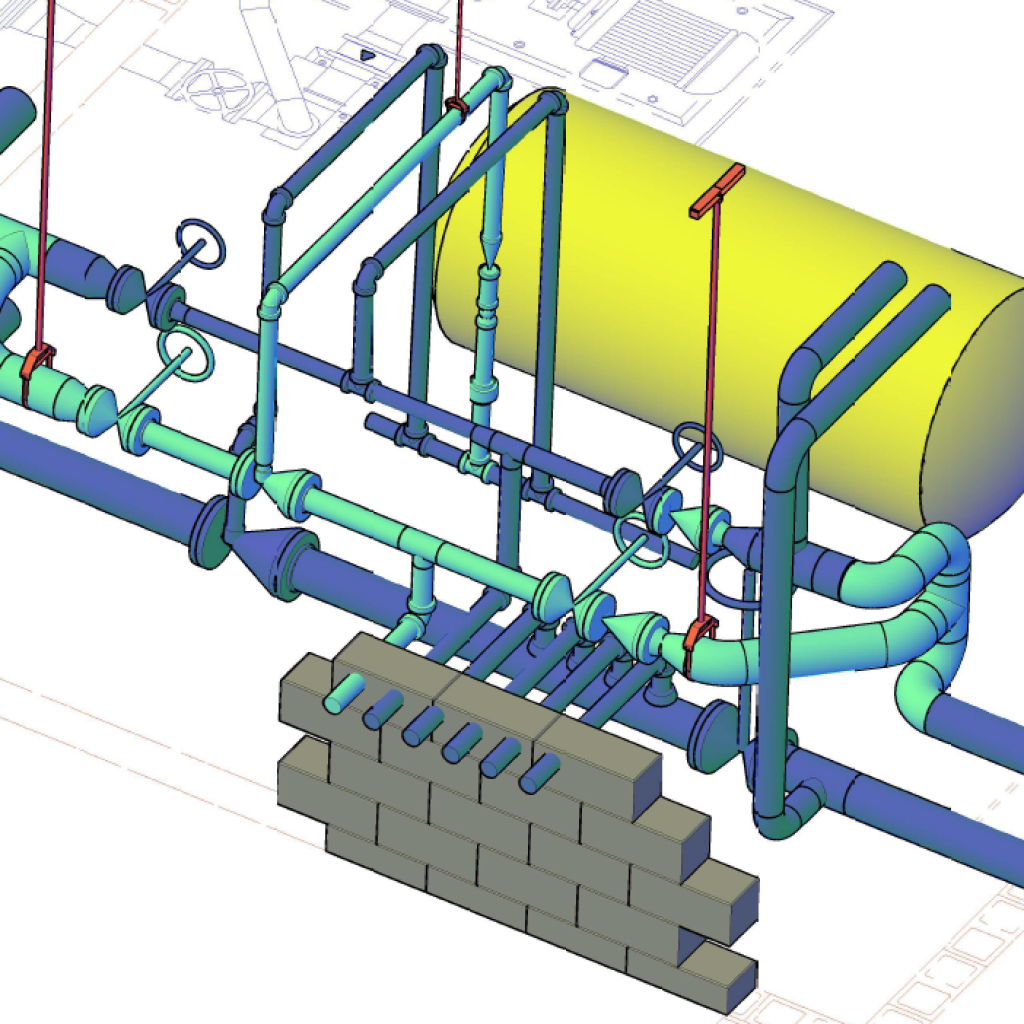

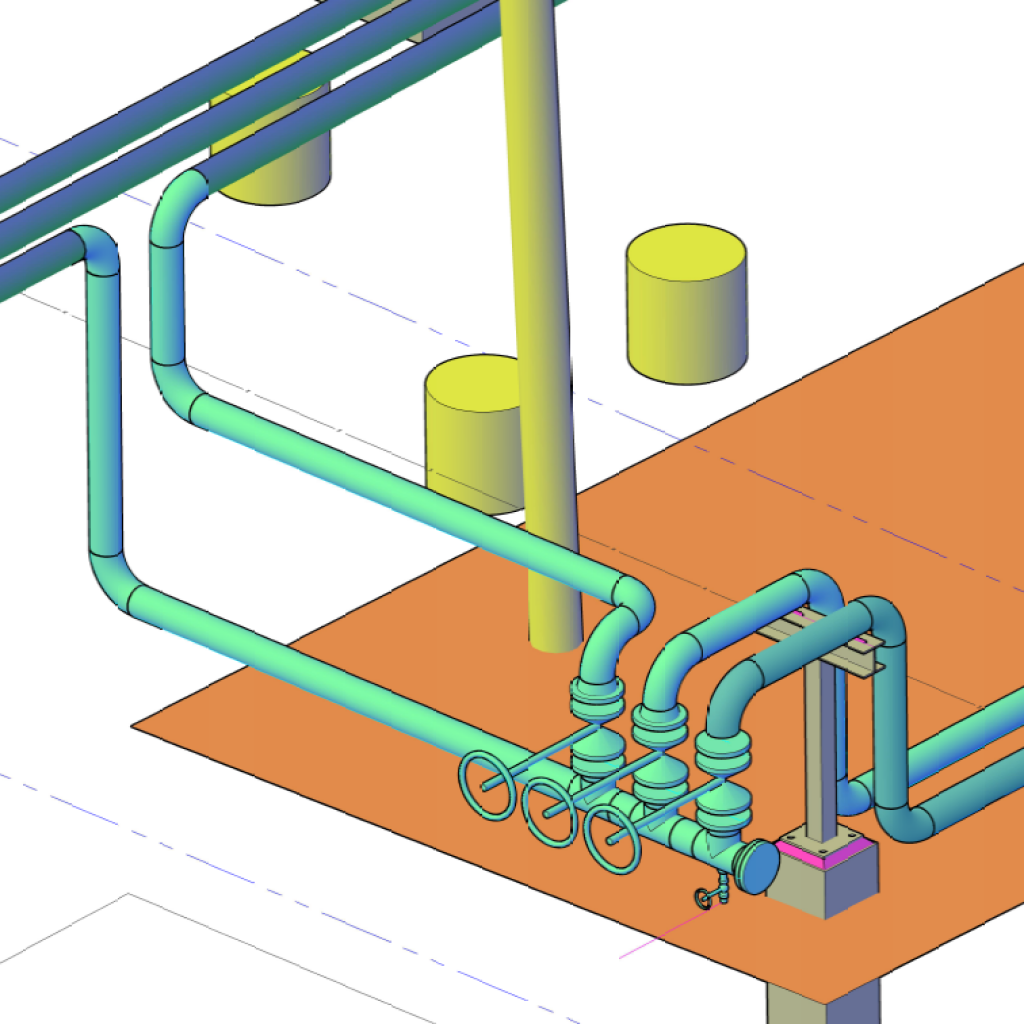

SPEC provided project development, engineering, permitting, drafting, procurement, and construction support for the installation of a new meter skid system and a three-quarter mile pipeline from a 3rd party to the client at a distribution terminal. SPEC’s role included assisting in the definition of the overall project scope, permitting, conversion of swamp land into a temporary island for directional drilling of a new pipeline, design of a new meter skid and prover system, installation of a new control building, and installation of a new gas chromatograph building. SPEC designed a new meter skid and pipeline to allow for installation in swamp land and to handle potential future flooding.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Electrical Engineering, Instrumentation and Controls, Mechanical Engineering, Design and Drafting, Permitting, Fire Protection, Procurement Support, Construction Management

Client: Major Oil Company

Project Location: Southeast, USA