Projects

Process Vessel Platform

SPEC provided 3D scanning technologies, detailed engineering design services, fabrication, installation, and construction oversight of a vessel access platform structure for a pharmaceutical client. The vessel, which was located within a process clean room, required a stairway and platform for access to the top of the vessel. The design included a permanent sleeve to anchor a mobile confined space hoist system, allowing personnel to safely enter the vessel for inspections and other vessel maintenance. SPEC utilized an in-house 3D laser scanner to accurately model the existing area of the proposed structure.

Terminal Modernization

SPEC provided project development, engineering, permitting, drafting, and procurement support for the modernization of an older terminal. SPEC was brought in at the beginning of the project to develop initial scoping, perform feasibility studies, and develop cost estimates and schedules.

SPEC was involved in permitting; conversion of a public road into a private road; rehabilitation of the dock, including new marine dock arms and piping interconnections to the ship and barge facilities; new marine vapor destruction units and safety skids;

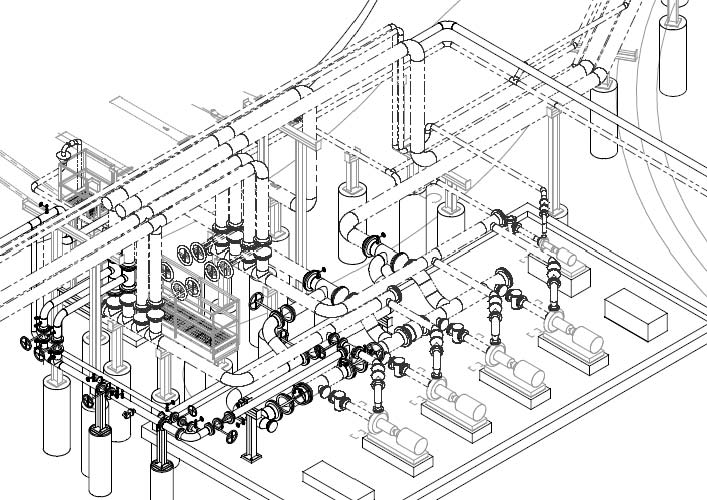

Direct Truck to Tank Butane Blending

SPEC engineered the installation of a direct truck to tank butane blending system at a client’s terminal. The upgrades included a custody transfer quality butane truck offloading area, installation of butane blending nozzles in four storage tanks, a new ANSI recirculation pump, installation of a fast loop butane/gas blending system, and the associated control instrumentation.

Services Provided: Project Development, Permitting, Engineering, Design, Procurement, Safety, Health, and Environmental.

Client: Major Oil Company

Project Location: South,

Marketing Terminal 50% Upgrade in Throughput

SPEC provided project support for the upgrade of a Petroleum Marketing Terminal. The upgrades included a new 84,000 BBL storage tank, (6) new ANSI rack supply pumps, a vapor recovery unit (VRU) upgrade including vacuum assisted loading, nearly a mile of new piping and valves, a new outdoor MCC, upgraded ethanol offload area, re-designed terminal traffic pattern, new automated exit gate, relocated additive tank farm and associated equipment, new load rack lane, canopy and three new skid mounted,

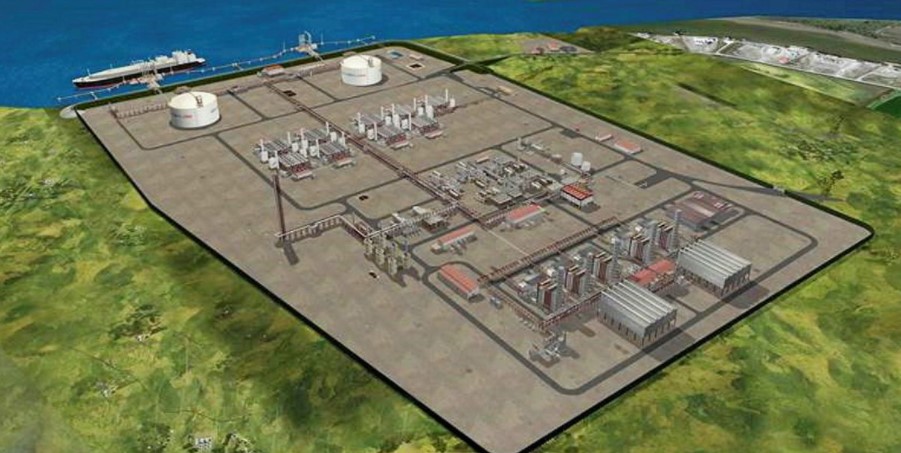

Professional Engineering Services for LNG Facility – Liquefaction

SPEC provided Professional Engineering Services for civil / structural design of the liquefaction (LTS) elements of an LNG Export facility located in the Southeast, USA. SPEC served as the Engineer of Record for the structural design of 18 Gas Process Mega Module units (Approx. 175 ft. by 75 ft. by 75 ft.) which support the equipment, piping and air coolers for the LNG facility in a three level structural system, 18 compressors and their supporting structures and walkways,