Projects

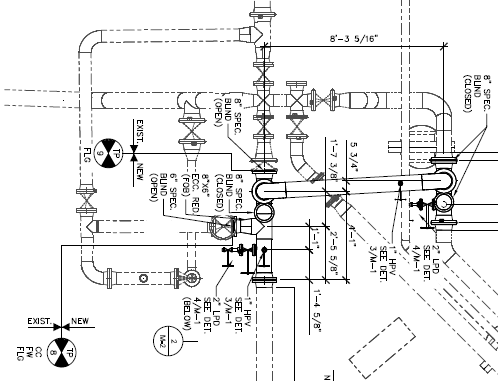

Tank to Tank Ethanol Transfer

SPEC provided support for the modification of terminal piping to allow for an existing regular gasoline tank to be used as an ethanol swing tank during a tank inspection at a refined products distribution terminal. SPEC designed new pipe spools and isolation valves to allow for unloading from, and loading to, the load rack at the new swing tank, field measurements of existing piping for drafting, stress analysis for new pipe spools, and creation of project record drawings.

Oil & Gas Facility Compliance & Risk Assessment

The project involved performing facility and equipment risk assessments on crude oil pipelines, pipeline pump stations, and terminal and tank facilities using the API Risk Management Methods in API Publication 353 Managing System Integrity of Terminal and Tank Facilities. SPEC performed the risk assessments and trained the Client engineers in the risk assessment and risk mitigation techniques at crude oil gathering facilities associated with the Client’s pipeline facilities. The goal of the risk assessments was to identify high risk facilities and components and develop a screening/ranking of high-risk facilities and equipment.

New Rail Car Unloading

SPEC provided multidisciplined engineering services (process, mechanical, civil, electrical) for unloading of ethanol and asphalt at a storage tank facility. The client required a backup unloading facility to supplement the existing marine unloading facility. SPEC designed the mechanical and civil portion of the rail unloading area. SPEC designed a new NG fired hot oil heater and hot oil heat tracing of the new asphalt piping. The rail car also required steam for offloading of asphalt.

Structural Assessment of Operational Equipment

SPEC’s Client required inspection of and condition survey of existing overhead conveyors at their quarry location. SPEC provided structural engineering assessment, design, and support services to complete the structural condition surveys of the existing conveyors. The project required SPEC to assess the condition of the conveyor structural supports, including foundations, to determine the adequacy of continued use and to determine required maintenance. SPEC designed repairs, replacement members or replacement of complete structural elements based on the condition assessments to allow the conveyor to continue to operate.

Marketing Terminal Upgrade

SPEC provided the engineering, procurement support, and construction management for the upgrade of a Petroleum Marketing Terminal. The upgrades included demolition of (2) existing tanks, installation of a new 45,000 BBL storage tank, (4) new ANSI rack supply pumps, (2) new (3) arm loading skids with meters, control valves, additive injectors, and instrumentation for ULSD and ethanol blended Regular, Midgrade and Premium Gasolines. New outdoor MCC and load rack control equipment were also installed.

Services Provided: Project Management and Design,