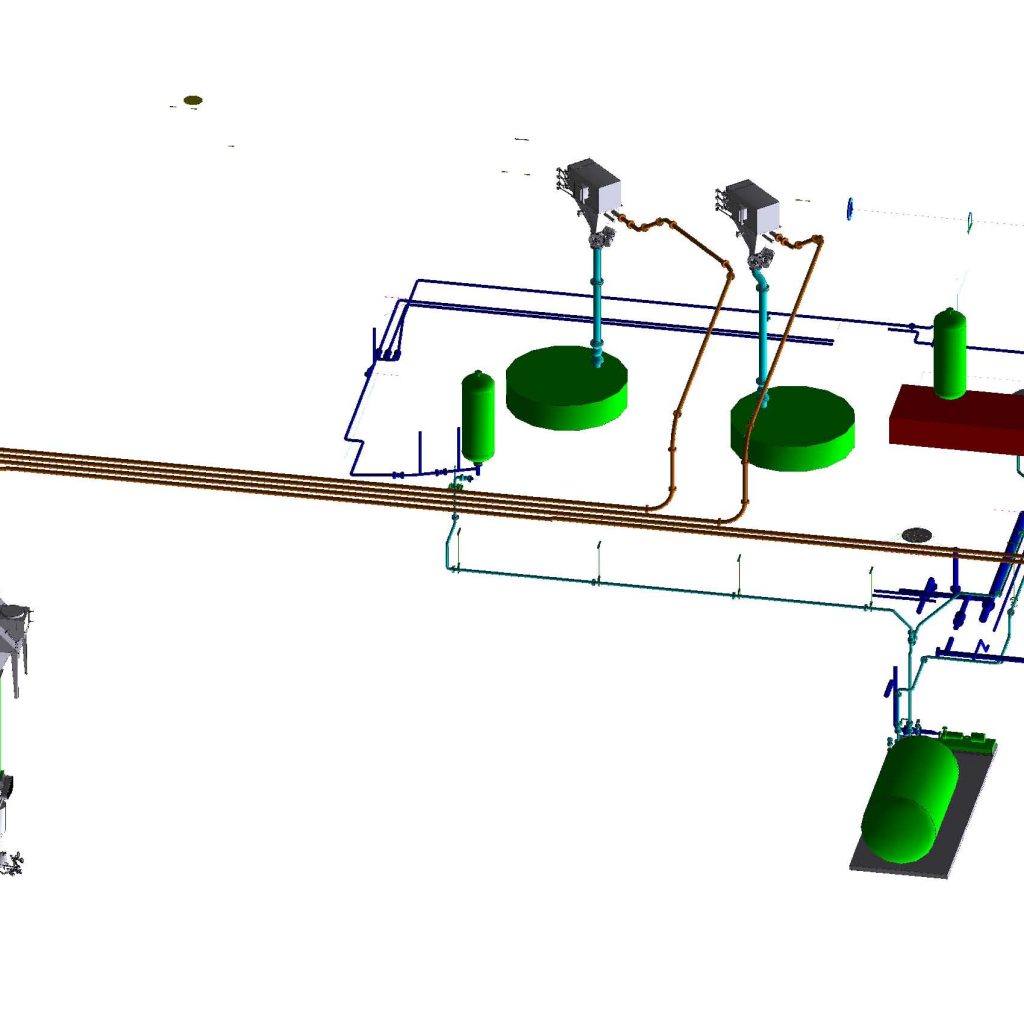

SPEC’s client desired the relocation of a specialty resin production process to another production building within the same facility. SPEC lead the relocation of the process and updated the design to include a new recycled phenol collection system, a new phenol storage tank, new pumps, new raw materials connections, steam and electrical heat tracing, insulation, and a recycled resin solids pneumatic conveying system to four existing reactors. SPEC oversaw significant aspects of the construction including the demolition of out-of-service glass-lined reactors and a crumbling second floor, as well as the installation of a new concrete second floor in the final location.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Electrical Engineering, Instrumentation and Controls, Mechanical Engineering, Design and Drafting, Safety, Procurement Support, Construction Management

Client: Major Chemicals Company

Project Location: Northeast, USA