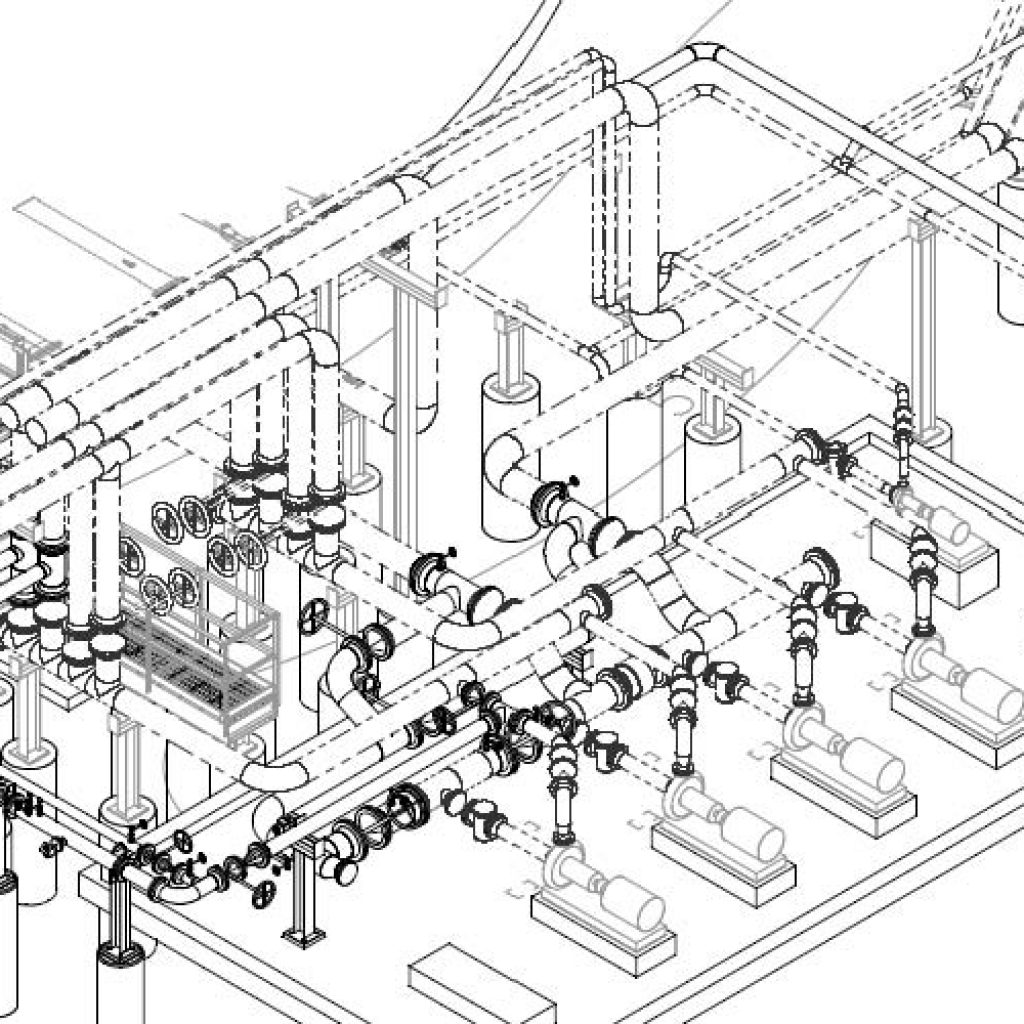

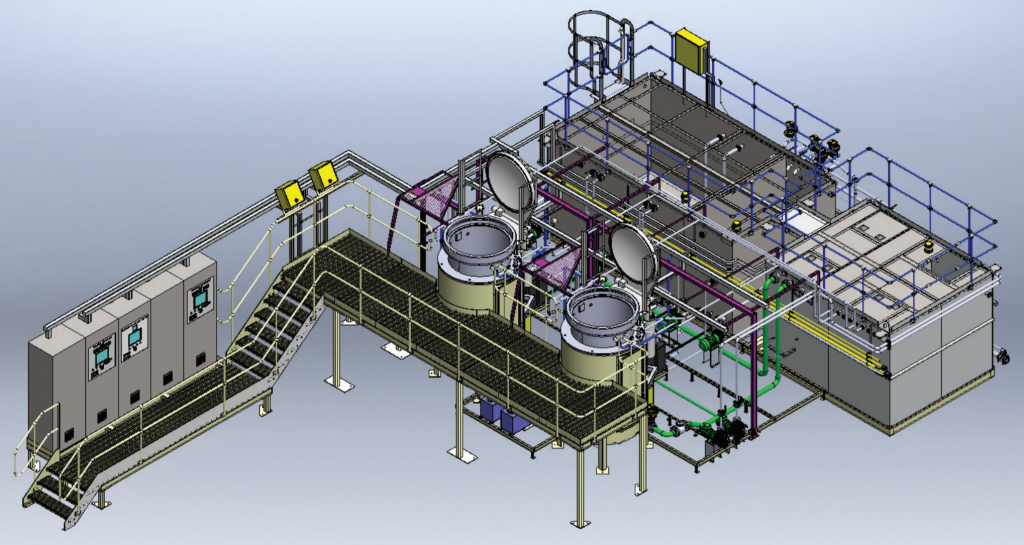

SPEC provided 3D scanning technologies, detailed engineering design services, fabrication, installation, and construction oversight of a vessel access platform structure for a pharmaceutical client. The vessel, which was located within a process clean room, required a stairway and platform for access to the top of the vessel. The design included a permanent sleeve to anchor a mobile confined space hoist system, allowing personnel to safely enter the vessel for inspections and other vessel maintenance. SPEC utilized an in-house 3D laser scanner to accurately model the existing area of the proposed structure. SPEC’s structural and civil engineering team utilized the 3D model to design the platform within the space limitations of existing process equipment and piping. Calculations and construction drawings were prepared for the structural steel considering OSHA and IBC regulations for platform design loading and fall protection. SPEC secured and awarded the fabrication and installation of the platform and stair system to a local contractor and provided oversight for the field construction services associated with the installation. SPEC coordinated the project installation schedule directly with the Client and the contractor to coincide with an already scheduled brief shut down period for the process area. The structure was prefabricated off-site in sections sized for transport within the process buildings. On-site work was limited to the erection and connection of the prefabricated segments to reduce the installation time within the shutdown period. SPEC personnel completed site specific safety orientation to gain badge access to restricted clean rooms to complete the work scope. Final walk-downs with the client of the installed platform davit systems were conducted to obtain acceptance of the finished product prior to releasing the construction contractor from service. SPEC maintained and provided record drawings for the work.

Services Provided: Process Management and Design, Civil/Structural Engineering, Design and Drafting, Scanning & 3D Modeling, Safety, Construction Management

Client: Pharmaceutical Company

Project Location: Northeast, USA