Projects

Emissions Control Upgrade

SPEC provided the engineering and procurement support for the installation of a new Vapor Recovery Unit (VRU) with vapor vacuum assisted loading at a client’s terminal. The upgrades included a new VRU with continuous inlet and outlet monitoring instrumentation, a new control building, new instrument air system including a new air compressor, desiccant dryer, accumulator vessel and associated instrumentation and controls. A new vapor vacuum control system with new vapor blower, header pressure control, individual truck lane load rack pressure controls,

Recycled Polystyrene

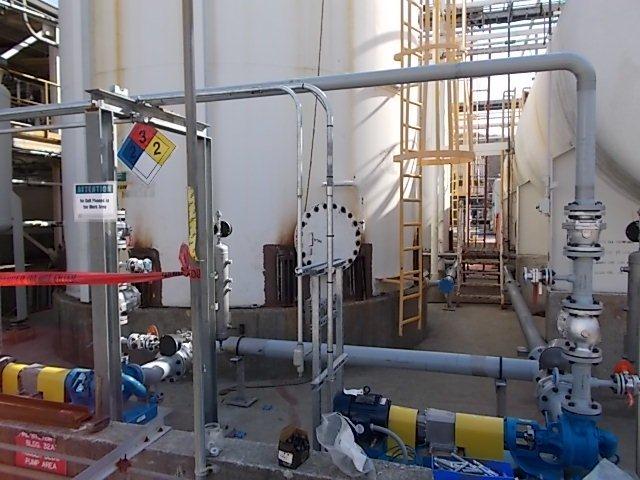

SPEC provided project development, engineering, drafting, procurement, and construction support for the installation of polystyrene recycling equipment. The project installed new pneumatic conveying equipment and support structure to unload trucks carrying recycled polystyrene solids into storage silos. The project also included pneumatic conveying equipment, including hundreds of feet of piping, filter receivers, diverter valve, rotary valve, and automated knife gate valves, to convey and measure recycled polystyrene solids to dissolver tanks. SPEC designed a new structure to contain pumps,

Load Rack Expansion & New Ethanol Tank

SPEC provided project development, engineering, permitting, drafting, and procurement support for the gasoline throughput increase and addition of a new ethanol blending system and storage tank at a distribution terminal. SPEC’s role included assisting in the definition of the overall project scope, permitting, design and layout of a new vacuum assist system, design of new storage and a new load rack supply pump, and the installation of a new loading system for ethanol blending into gasoline at the loading rack.

Rail Offload Facility Design & Main Terminal Expansion

SPEC provided support for a major terminal expansion project to build a new offsite ethanol and butane rail offload facility at a greenfield location and the associated infrastructure improvements at the main terminal. The scope of work included design of the rail site stormwater retention pond system (including facilitating flora mitigation and fauna relocation), tank containments, and all major equipment foundations. SPEC performed the mechanical, civil, and electrical design of the new rail off load facility and for the piping system design and modification at the main terminal.

Leach/Etch Process

SPEC’s client started up a new caustic leaching autoclave and required assistance to refine the leach/etch finishing process. SPEC was brought on to operationalize the leach system, which expanded into troubleshooting the leach process to improve the removal of the ceramic core from the product through experimental iteration, while training operators, creating SOPs, and developing the record-keeping system. SPEC aided the lab-scale acid etch process with troubleshooting to attain consistent results, then designed and provided procurement support for the pilot-scale etch process.