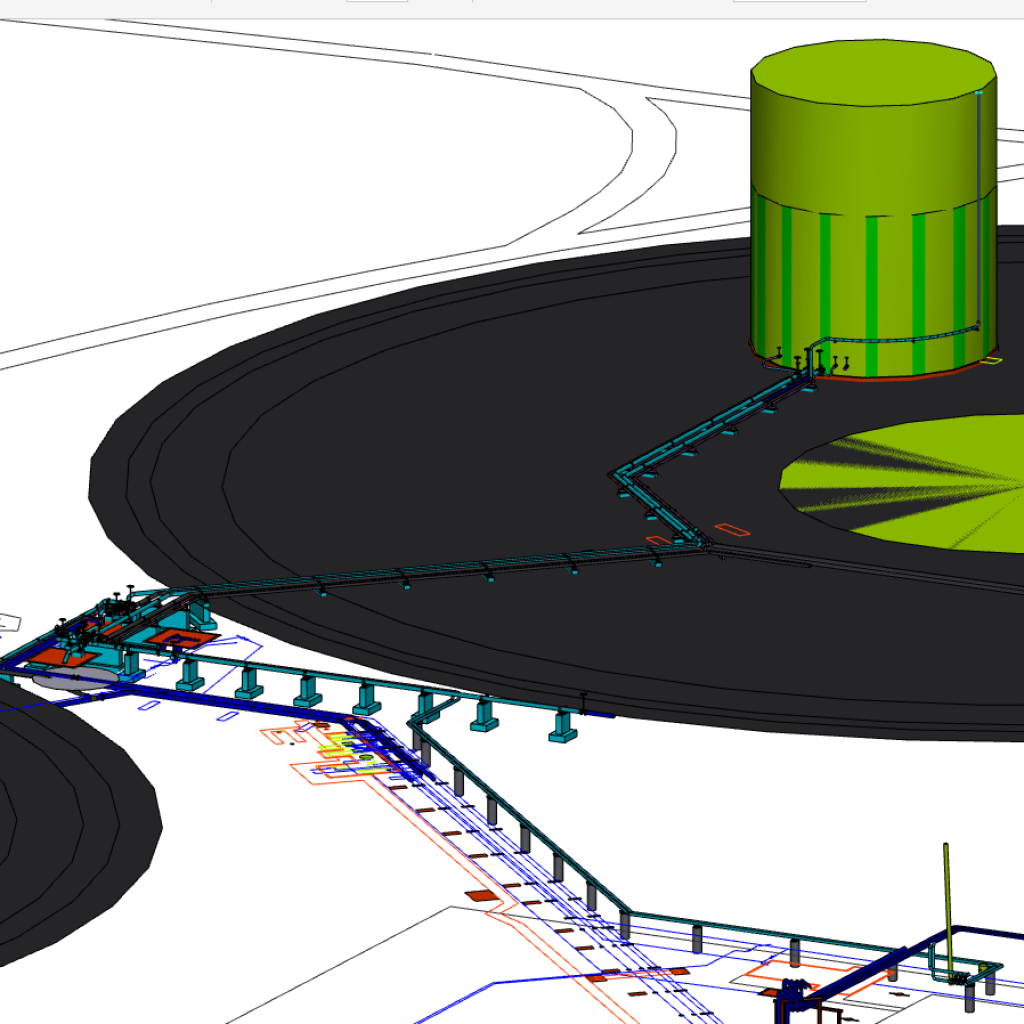

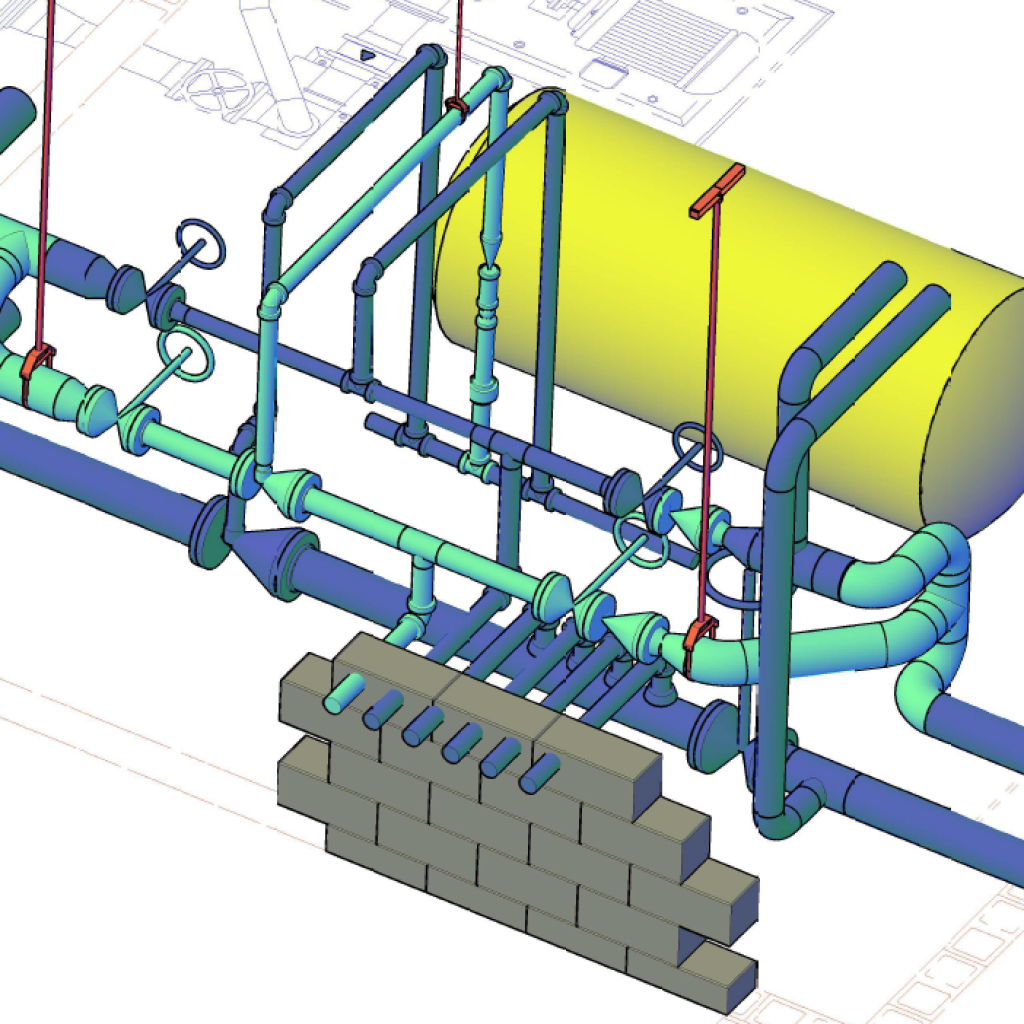

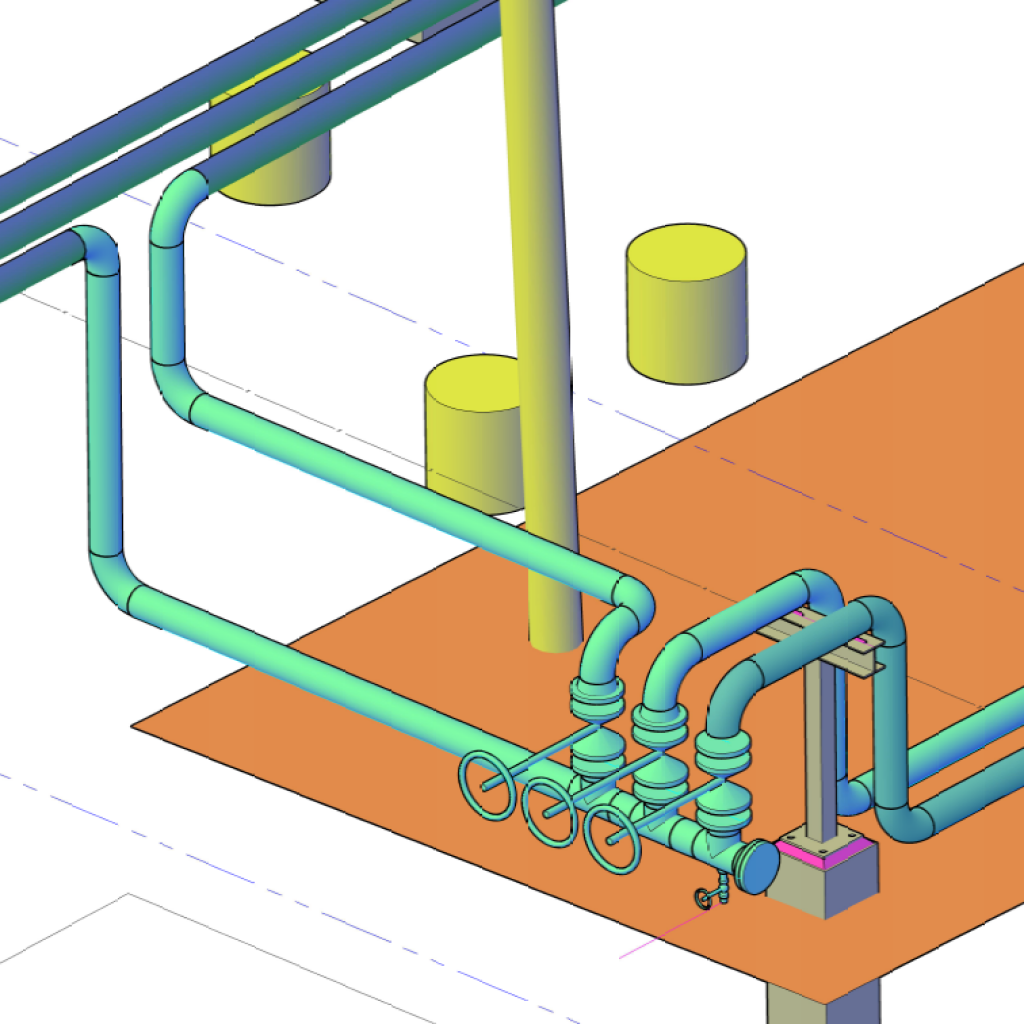

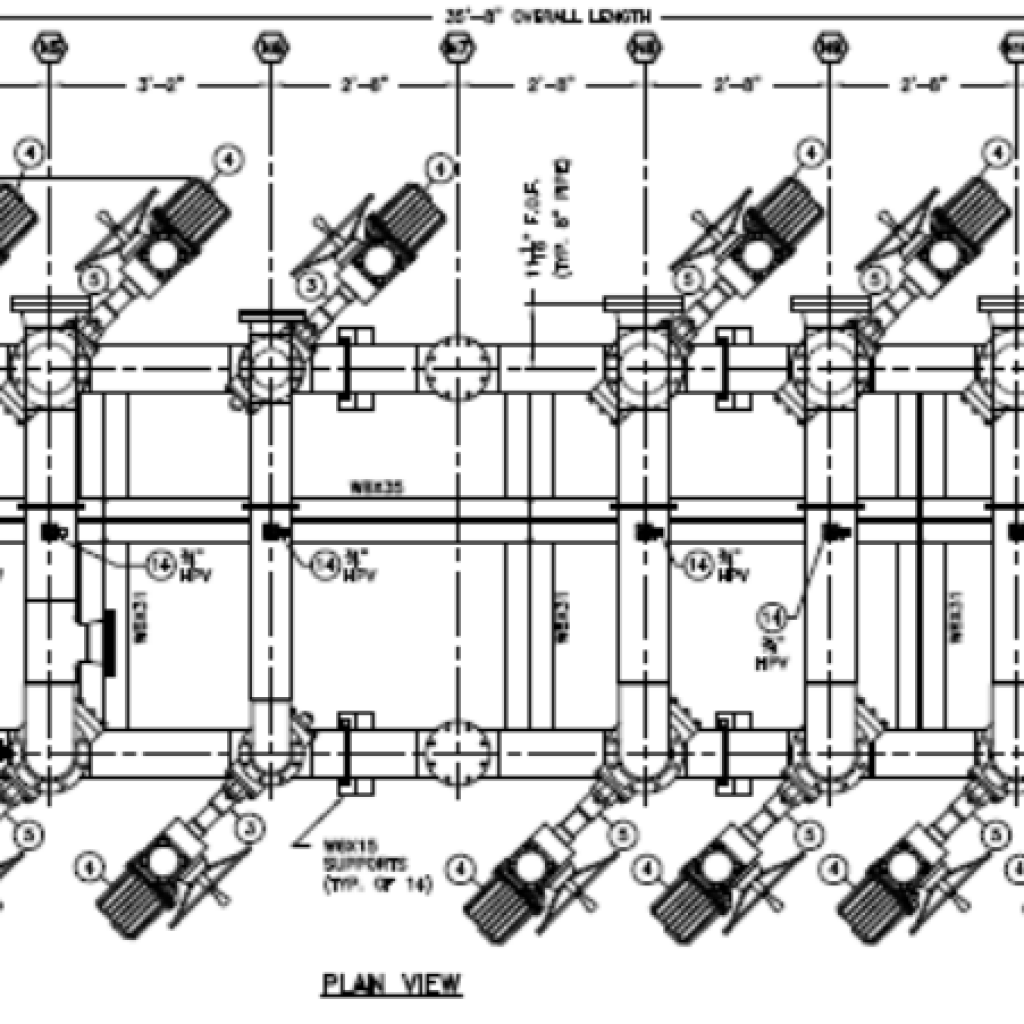

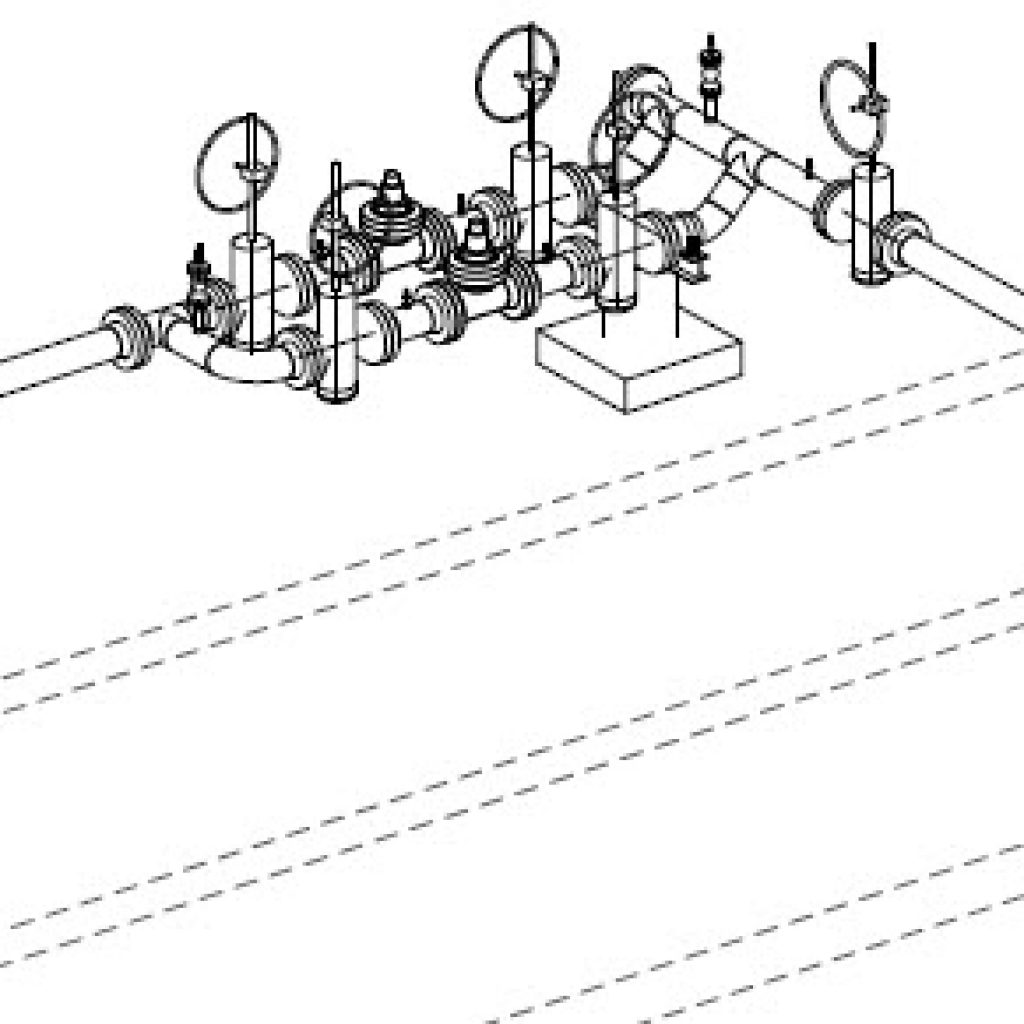

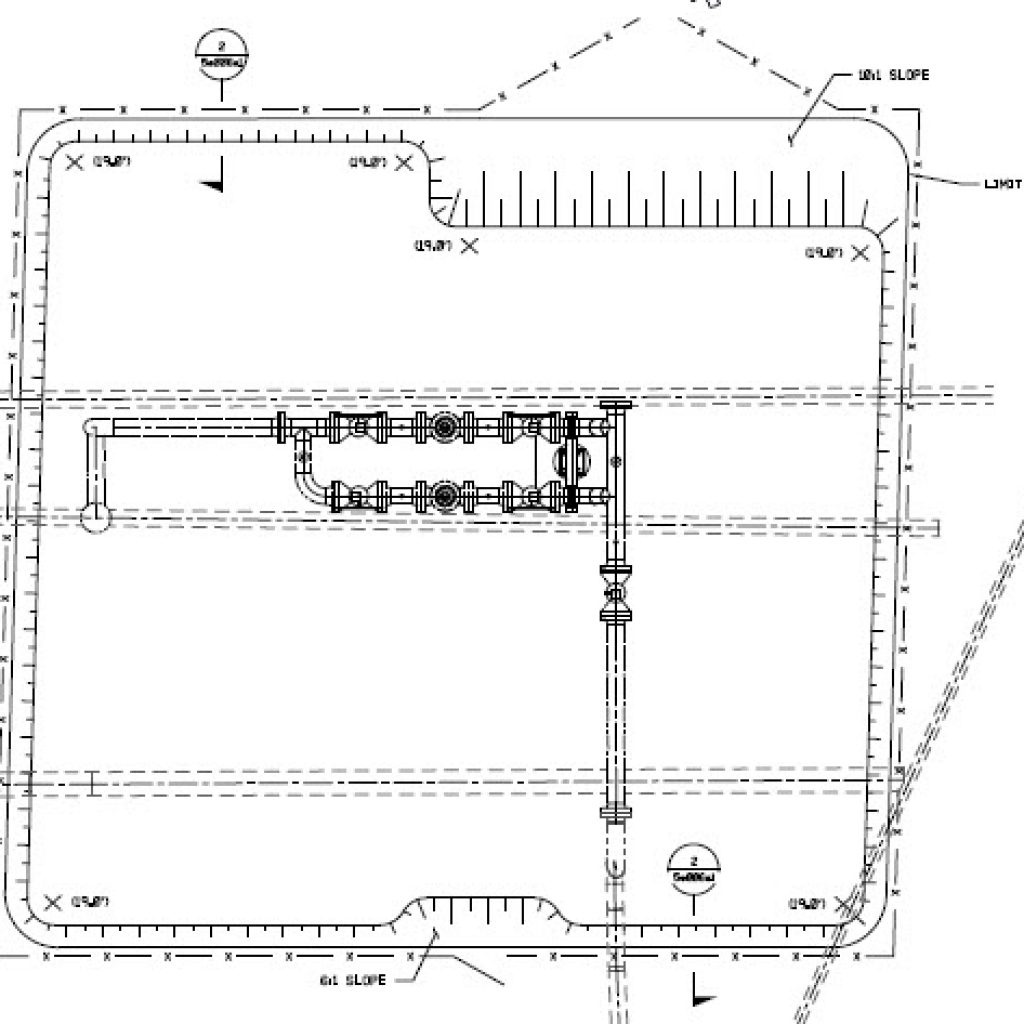

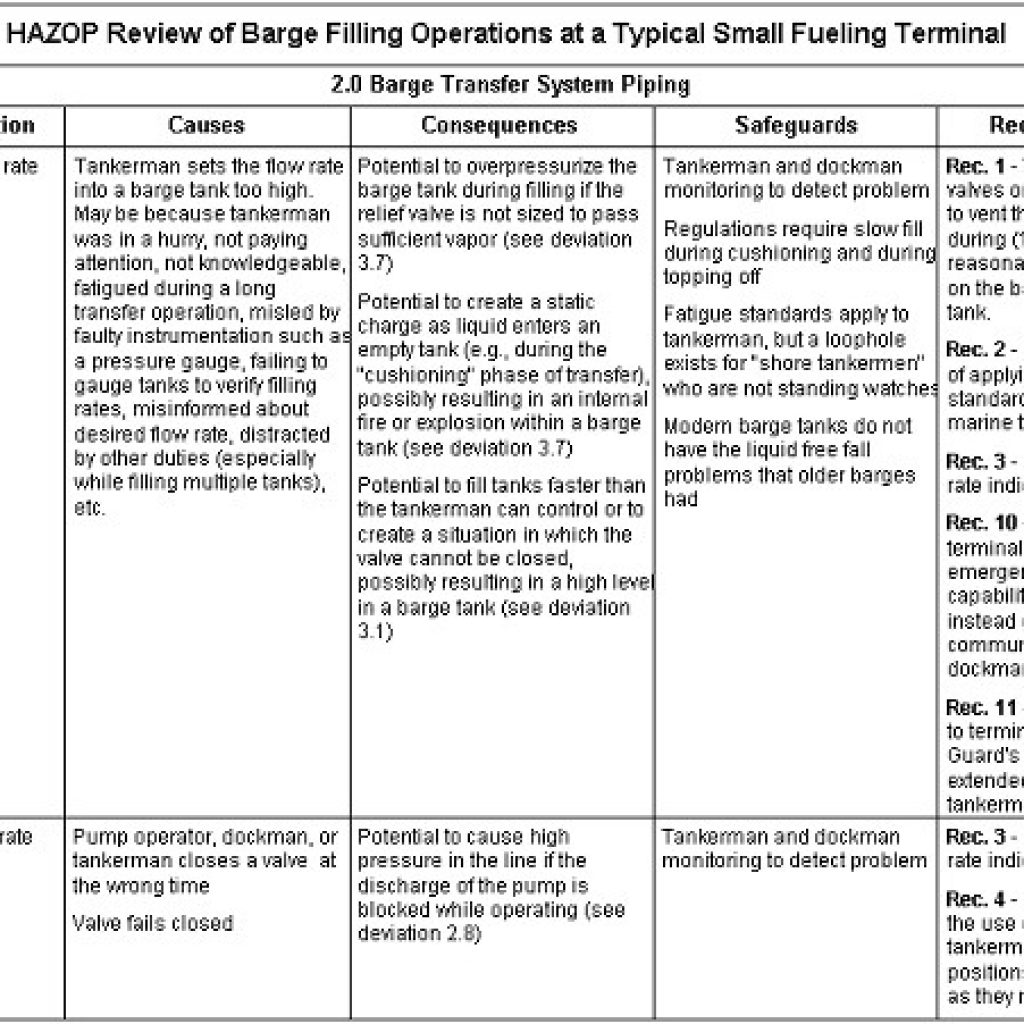

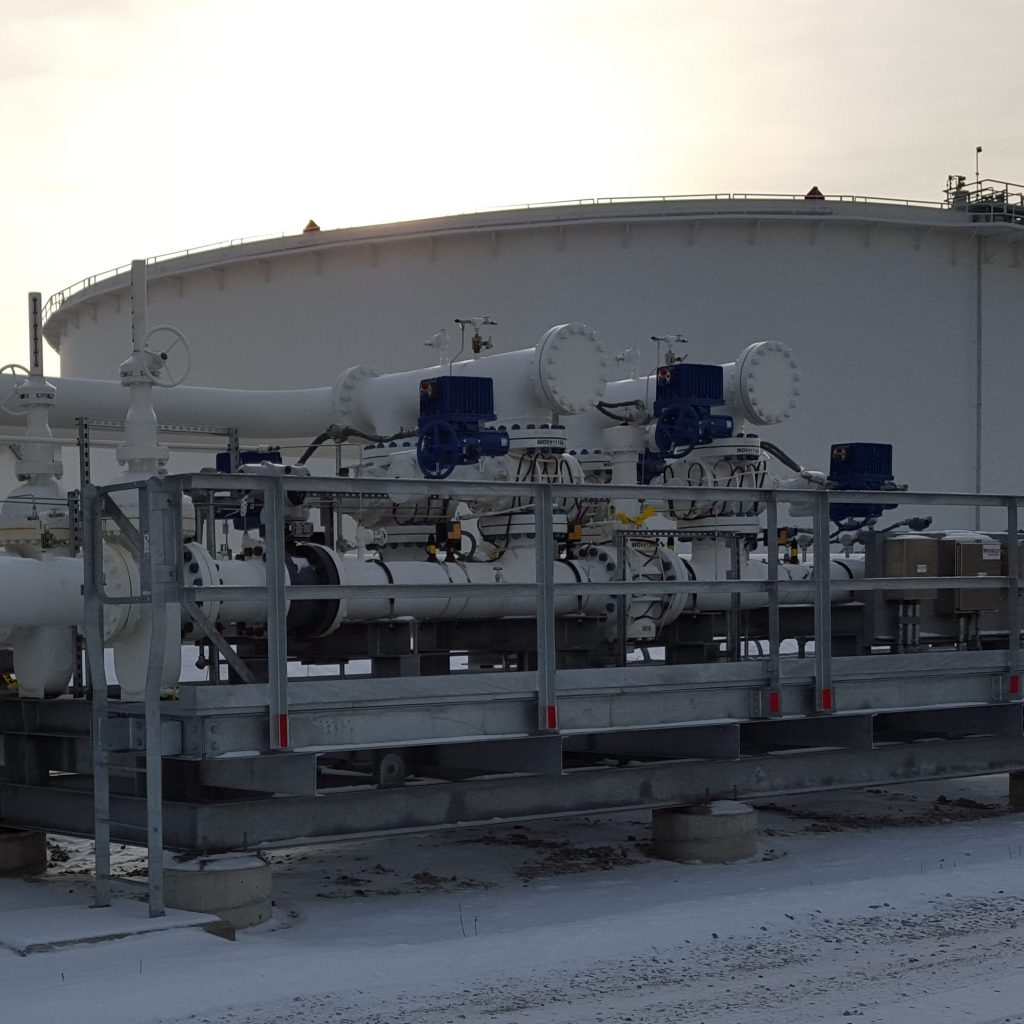

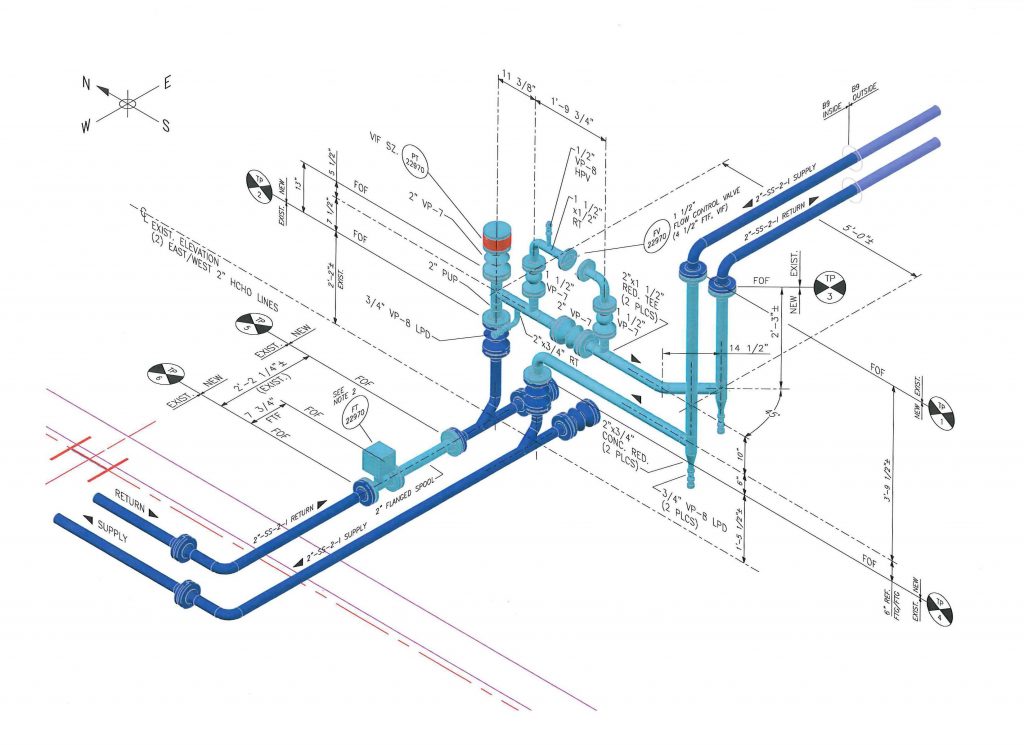

SPEC provided project development, engineering, permitting, drafting, procurement, and construction support for the addition of a new customer gasoline additive injection system at 17 distribution terminals across the United States. SPEC’s role included assisting in the definition of the overall project scope, permitting, modification of existing additive systems, installation of new additive systems (i.e. injectors, pumps, injection points, piping, tubing, etc.), and design and installation of new additive tanks. SPEC’s design and project scope allowed for the distribution terminals to handle roll out of new gasoline additive across the United States.

Services Provided: Project Management and Design, Process Engineering, Civil/Structural Engineering, Electrical Engineering, Instrumentation and Controls, Mechanical Engineering, Design and Drafting, Procurement Support, Construction Management

Client: Major Oil Company

Project Location: Continental USA