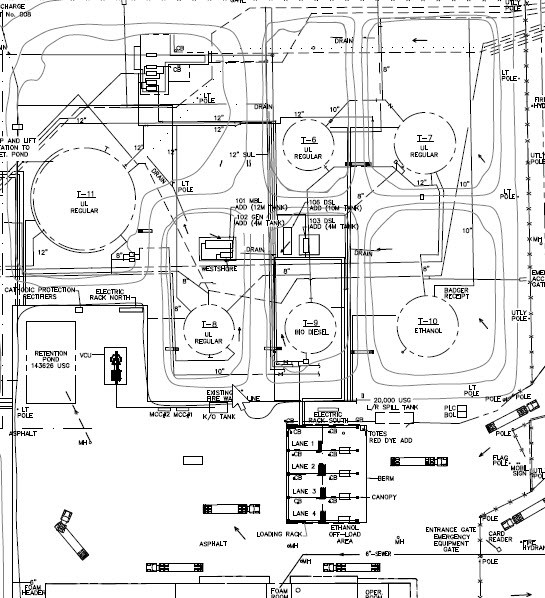

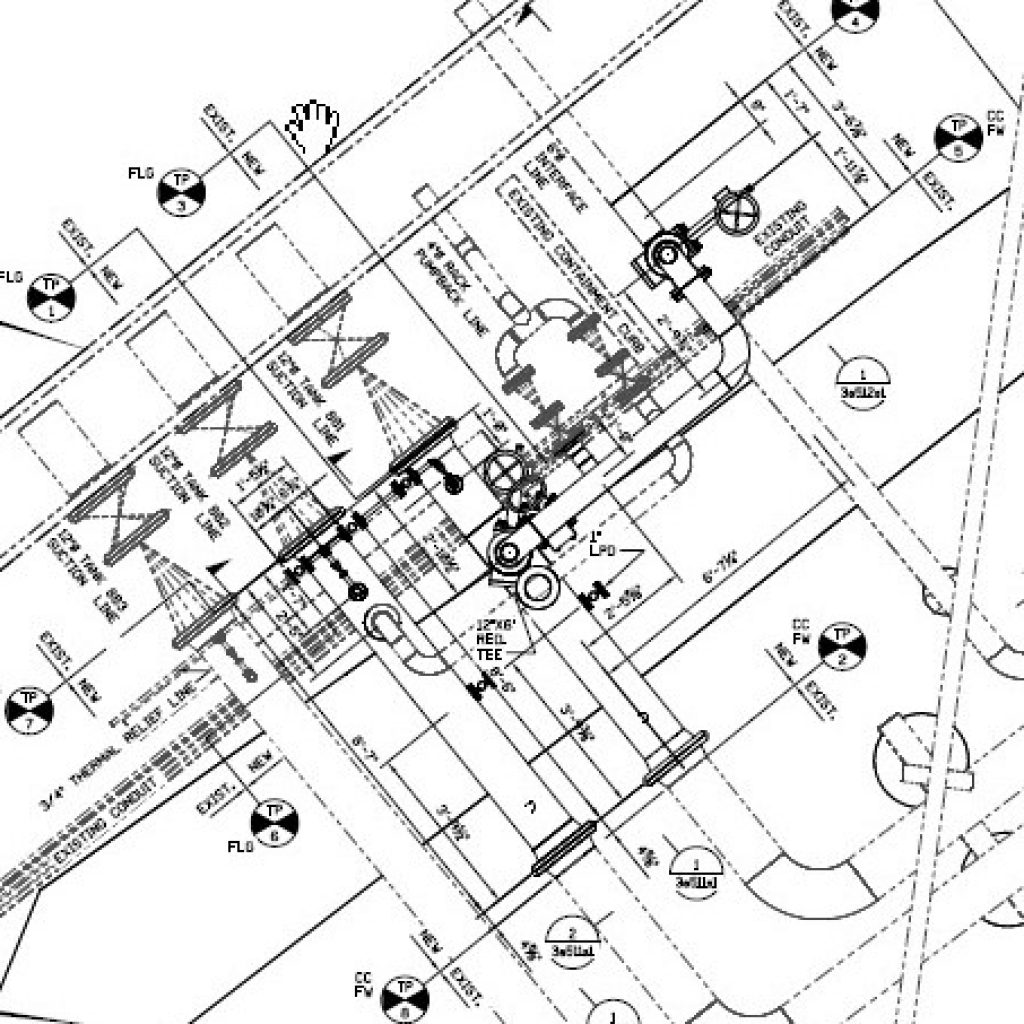

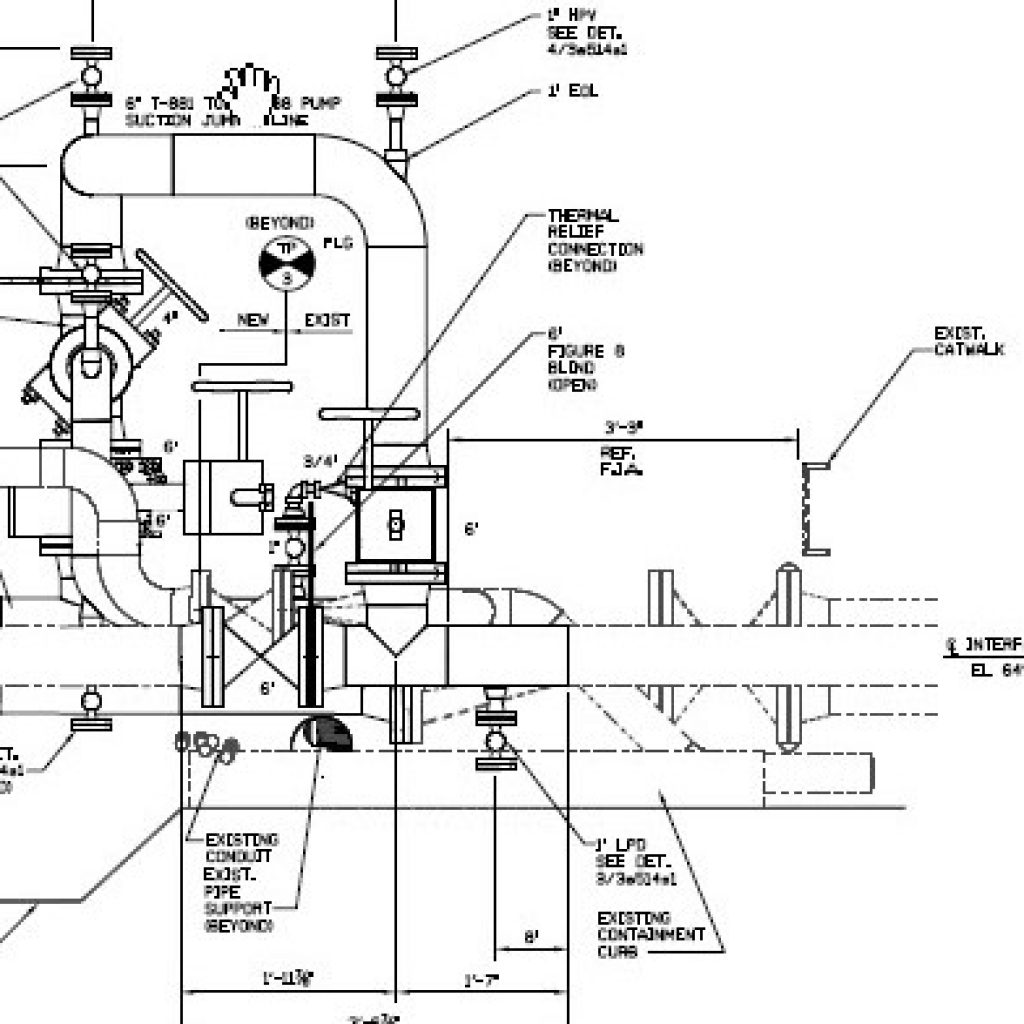

SPEC provided multidisciplined engineering services (mechanical, civil, electrical and API Std 653 inspection) of two jet fuel tank farms. The Client had two aging tank farms located in different cities. The existing configuration had excess tankage, aging infrastructure, and permeable secondary containment. The Client could allow for shutdown of one site at a time to complete the work. SPEC reconfigured each tank farm to four main product tanks and two day tanks for storage of Jet A & JP-8. A new single bay loading/unloading rack was added, new piping and pumps, new tank instrumentation and pump control system, impervious liner (under tank and diked area), new stormwater collection and OWS treatment system. SPEC worked with the Contractor to move the tanks out of the area and relocate onto new foundations within the consolidated footprint.

Services Provided: Multi-disciplined engineering

Client: Multinational Industrial

Project Location: Northeast, USA